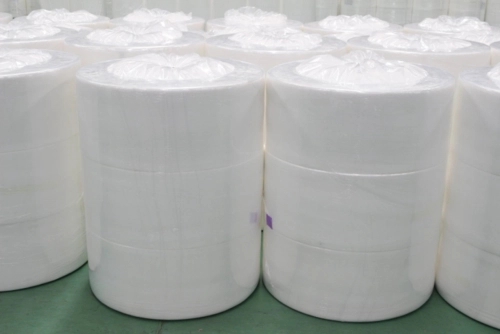

Bfe 99 PP spunbond melt blown nonwoven fabric for face mask

Date:2022-4-04 Author:

The melt blown nonwoven fabric specification is:

1) 100% PP polypropylene raw materials, referred to as “MB without any additives;To do common melt-blown BFE BFE – 99-95, for a variety of masks filter material

2) g: 15-300 grams;

3) width: 1.65 m, can be cut;

4) with good softness, non-toxic, antibacterial, fog/virus filtering

5) can double composite hot rolling was used to clean cloth/spun-bonded fabric with ultrasonic composite q, hydrophilic after MATS and other health care products used in surgery.

How does the melt blown machine work

This polypropylene (PP) spunbonded nonwoven fabric production line has advantages of superior performance, beautiful color, and good quality. It can form a fibre web symmetrically and is complete in types. It can also add recycled material and stuffing to reduce the cost of products.

This melt blown nonwoven fabric machine is used for polypropylene fiber spinning web, hot rolling and strengthening nonwoven fabric production. The melt hot-rolled PP nonwoven fabric with different colors, functions and applications are produced with polypropylene fiber as the main raw material, supplemented with color masterbatch and additives such as anti-oxidation, anti pilling and flame retardant. The production line can not only produce three-layer SS polypropylene spunbonded nonwoven products, but also produce three-layer S-M-S and four-layer S-M-M-S products. At the same time, the production line can produce melt blown nonwoven fabric for mask by adding off-line melt blown device.