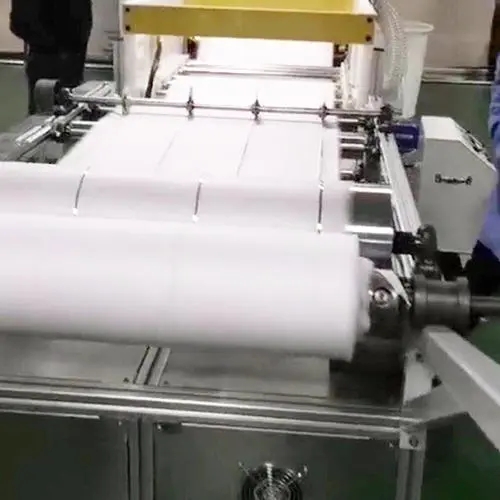

Melt blown extrusion machine with good quality

Date:2022-4-04 Author:

Application of the melt blown extrusion machine:vHealth Care: Medical Face Mask; Baby diaper; Women sanitary napkin and so on.

Usage of melt blown cloth

PP is the main raw material of the melt blown cloth, and the diameter of the fiber can reach 0.5-10 μ m. These ultra-fine fibers with unique capillary structure increase the number and surface area of the fiber per unit area, so that the melt blown cloth has good air filtration, and is a relatively good mask material. In large and medium-sized medical institutions, in earthquake and flood affected areas, in SARS and avian influenza With the high incidence season of H1N1 virus, melt blown filter paper plays an irreplaceable role with its strong filtering performance. Melt blown cloth is mainly used for:

a.Filter material

b.Medical and health materials

c.Environmental protection materials

d.Clothing materials

e.Battery diaphragm material

f.Wiping materials

Melt blown extrusion machine production line has high efficiency and high quality non-woven production capacity. The effective width of the cloth is 1.6m, and the speed of the production line can reach 400 m / min. The output cloth is widely used, especially in health protection.

Advantages:

1.New production process of Raffin, positive pressure ultra high speed air flow

2.Production line use “slit suction drawing” technology

3.siemens electrical control system

4.The hot pressing roller is heated by heat conduction oil circulation, the ceramic roller surface is polished, and G4.5 level dynamic balance correction is carried out

5.Lower draft, lateral air supply function, internal lifting adjustment

6.It can be equipped with high-speed Slitter, cloth storage guide rail and electric hoist

7.The number of S and M systems that can be selectively turned off or on.