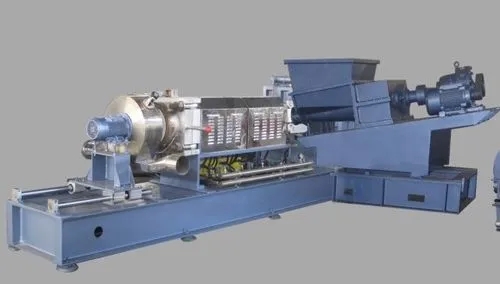

Hot sell plastic recycling granulator pelletizer extruder machine

Date:2022-4-03 Author:

Screw pelletizer extruder is a molding machine that can make materials into specific shapes.

Pelletizer extruder for granule productions/plastic extruder

Pelletizer extruder can be used in the process of various plastic granulation particles, which can be used for PP,PE,PS,ABS,OPPand other

plastics to granulate. For several characteristics and advantages of granulator, it is particularly remarkable in the following places:

1) The screw part is carefully developed and designed, the whole machine and each part are equipped reasonably, and all the lines

are heated by three fires and one zero.

2) The screw is designed according to the characteristics of the material, so the granulator has high efficiency and speed, the

products produced have strong gloss, the particle size is full, the configuration of the whole machine is increased, and the

service life of the equipment is added. In the appearance aspect has also carried on the rationalization design, therefore has the

unique aesthetic feeling.

3) This granulator adopts reasonable design, the production volume has also been greatly improved, the finished product

performance-price ratio is higher, the maintenance time is reduced, so the maintenance cost of users is also reduced.

4) The characteristics of high output and low energy consumption are equipped with large torque reducer and motor, and the screw

is specially designed and processed. No dead angle, no iron jam, effectively improve the production capacity, enhance the plastic

plastic effect. Equipped with single exhaust double exhaust structure, full drainage, exhaust, so that the particles are more strong and full.

5) High quality electrical and driving equipment to make the granulator more safe and reliable in the process of use.

Then how to choose pelletizer extruder? Let me explain to you.

1, with the mother machine, twin screw feeding.

2, the reducer is better, the gear inside must be heat treated, bearing adjustable.

3, transmission, screw, barrel, nose and wear parts should be treated with strength, life assurance of more than 1 year.

4,The main parts should be made of standard materials.

5, reducer and motor to buy professional manufacturers to produce sets, do not buy their own assembly of granulator manufacturers.

6, to have a power distribution cabinet.

7, the most critical equipment is the screw and barrel quality is good.

8, the washing machine must be continuous production, do not need to stop the water change, with cleaning pool, otherwise the efficiency is very low.

9, heating should be segmented, segmented heating should be uniform and controllable.

10, there should be a supporting waste plastic cleaning machine, using circulating water, no sewage discharge.

11, efficient electricity saving.

12, the length-diameter ratio of the machine can not exceed 20 (in 16:1-20:1 is appropriate, that is, the length of the screw is 16-20 times the diameter of the screw).

13, the model shall not be smaller than 100, the larger the output is higher.

14, to have double exhaust.

15, the heating power of the pelletizer flange (die head) is very important, and it should be designed according to 2.5W per square centimeter (cross-sectional area).