How to choose pelletizing machines

Date:2022-3-18 Author:

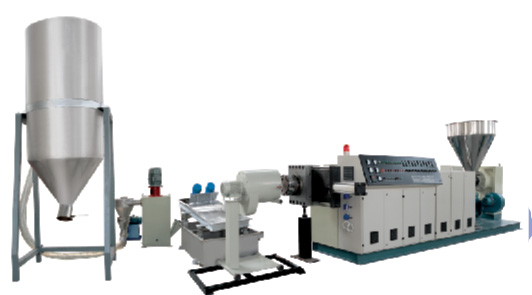

The plastic pelletizing machines are used to waste plastic recycling. The machines use high efficinet compactor force feeder, excellent screw, strong vacuum degassing system ,fast hydraulic sceen change,Vertical die face cuttuer,automatic vibrator screen.

Raw material for pelletizing machines are:PP, HDPE, LDPE, LDPE,BOPP,PLA Film, Woven bags/Nonwoven bags/Jumbo bags/ Raffia bag material.

Buying Guide for pelletizing machines

The pelletizing machines provide four different pelletizing solutions for your aiming at different MFI polymer and they can get different shapes output pellets.

1,With the mother machine, twin screw feed.

2, The reducer should be better, the gear inside must be heat treated, adjustable bearing.

3, Transmission, screw, barrel, nose and wear parts should be treated with strength, life assurance is more than 1 year.

4, The main parts should be made of standard materials.

5, Reducer and motor to buy professional manufacturers to produce sets, do not buy their own assembly of granulator manufacturers.

6, The pelletizing machines must have a power distribution cabinet.

7, The most critical equipment is the screw and barrel , the quality is good.

8, The washing machine must be continuous production, do not need to stop the water change, with cleaning pool, otherwise the efficiency is very low.

9, Heater should be segmented, segmented heating should be uniform and controllable.

10, There should be a supporting waste plastic cleaning machine, using circulating water, no sewage discharge.

11, Efficient electricity .

12, The length-diameter ratio of the machine can not exceed 20(in 16:1-20:1 is appropriate, that is, the length of the screw is 16-20 times the diameter of the screw).

13, The model shall not be smaller than 100, otherwise the output is higher.

14, Double exhaust.

15, The heating power of the pelletizer flange (die head) is very important, and it should be designed according to 2.5W per square centimeter (cross-sectional area).

16,The pelletizing system is available for 24 hours working non-stop operation.