High quality dimple plastic drainage board made in China

Date:2022-4-14 Author:

Plastic drainage board alias plastic drainage belt, wave type, harmonica type and other shapes. Extrusion molding plastic core board is among. It is the skeleton and channel drainage belt. It’s cross section is parallel cross, both sides with nonwoven geotextiles package filter layer. It’s core belt supporting role and will be filtered through filter layer water discharge upwards, is silt, silt soil. Such as filling soil saturated cohesive and miscellaneous fill use of drainage consolidation method for soft foundation treatment of good vertical channel, greatly shorten the soft soil consolidation time.

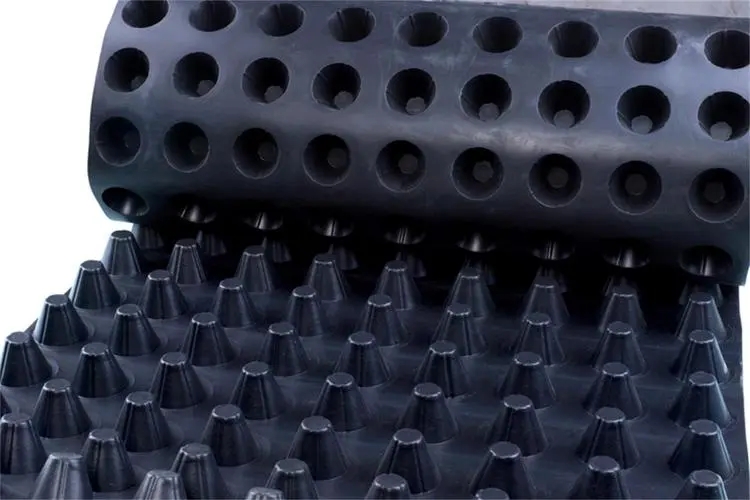

Plastic drainage board is made of polyethylene (HDPE) as raw material plastic bottom plate by punching into a cone or convex point of the stiffening rib (or hollow cylindrical porous), after continuous research and development of raw materials are changed, the compressive strength and overall flatness have a large width of 1~3 meters, length of 4~10 meters or more. Can resist long – term high pressure, no deformation. This long-term compression resistance can not only withstand the weight of the concrete floor and what, can withstand the inevitable external pressure and impact force during the construction, such as vehicles, workers and concrete pouring force. Long-term maintenance of floor invariance, so that the original displacement can be maintained. The geotextile filter layer on the bottom plate is used to ensure that the drainage channels are not blocked by foreign matter such as backfill soil particles or concrete.

This is a kind of functional material with many potential functions. Using this kind of sheet can be used to construct aerial layer very conveniently. The use of overhead layer to form drainage, exhaust channels, the same use of overhead layer to achieve the function of sound insulation, vibration isolation.

The top surface of the conical projection platform is glued with a layer of filter geotextile to prevent the passage of soil particles, thereby avoiding the blockage of the drainage channel and making the channel drainage smooth. The traditional drainage method uses masonry tiles as a filter layer, and uses more pebbles or gravel as a filter layer, and drains the water to a designated location. The use of drainage boards to replace the cobblestone filter layer to drain water saves time, effort and energy, saves investment, and can also reduce the load on the building.

A good drainage system plays an important role in the construction period of civil works and the normal use and life of structures. The plastic drainage board and the porous pipe form an effective drainage system, and the cylindrical hollow drainage plate and geotextile also form a drainage system, thus forming a system with water seepage, water storage and drainage functions.

The advantages of plastic drainage board for strengthening soft soil foundation

Good filtration, smooth drainage, drainage effect is guaranteed.

The material has good strength and ductility, which can be suitable for foundation deformation without affecting drainage performance.

The drainage board section size is small, the drainage board in the process of small disturbance to the foundation.

Insert board construction can be carried out on super weak foundation.

The construction is fast and the construction period is short. Each board inserting machine can insert more than 5000m boards per day, and the cost is lower than bag sand well.

In terms of technology and economy, the drainage board is almost the only economical, effective and feasible method for deep soft soil foundation to be strengthened by drainage consolidation method.