Best quality WPC board machine manufacturer

Date:2022-4-10 Author:

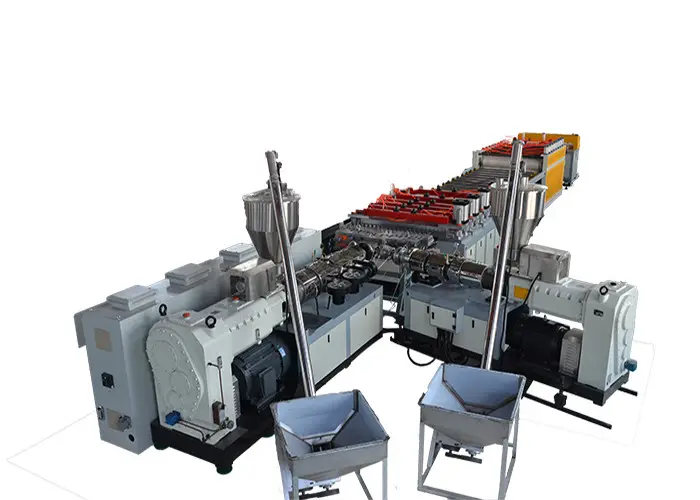

This WPC borad machine is used for making WPC profiles by Wood and Plastic composition, such as WPC decking, WPC wall cladding, WPC fencing, WPC pergola, WPC post, etc.

The WPC profile production line can continuously produce WPC profile. The WPC profile adopts two-step production process.The first step is using WPC granulating machine to make WPC pellets from recycled PP/PE material,wood powder and chemical additives.The max wood percentage can be 70%.The the WPC profile extrusion line will make the WPC pellets into WPC profiles by equip customized mold.We can equip on-line embossing machine to achieve 3D wooden pattern.

PVC WPC profile extrusion line

The profile produced by this production line can be sanded and brushed by sanding machine and brushing machine.

Introduction of the wpc board machine

Advantage of wpc board machine.

1. It can produce PE, PP or PVC wood-plastic of by applying specially designed screw, material cylinder, mold and processing production technology and auxiliary machines for shaped material, the line is Wood-plastic Extruding Production Line.

2.it may produce PE, PP or PVC wood-plastic different shaped products.

The wooden-plastic mixing extruding production line adopts special-designed screw stem, material cylinder, moulds and processing technology.

3.Equipped with YE model auxiliary it can produce wooden-plastic profile. It is a new kind of environment protection products which Mix plastic and waste wood fiber in proper proportion, adding plastic processing extender.

4.It can produce, package box plate, frame material for door and window, floor board, outside products extruded in high temperature and high pressure.

Wood-plastic board is a kind of synthetic board, not easy to deform, as interior decoration, furniture, etc., is the first choice of environmental protection materials.

Advantages of wood-plastic board:

A. The lowest loss: wood plastic belongs to profiles, hollow specifications, very good material saving, aluminum alloy doors and Windows so quickly popular, that is, the use of this profile, so as to reduce costs, the purchase price is not high naturally. Although the price is not tall, but intensity increases however, better than lumber door window too much.

B. Wood-plastic surface does not need to be treated: wood surface is to paint or water-based coating treatment, but wood-plastic board does not need, only need to use for 1 year to do maintenance or paint, the cost is far lower than wood products.

C. Service life: ordinary wood is 3-4 years, and wood-plastic board is said to reach 10-50 years.

D. Physical properties: non-slip, wear resistance, no cracking, aging resistance, corrosion resistance, anti-static and ultraviolet, flame retardant, can resist 75℃ high temperature and -40℃ low temperature, etc.

E. Environmental protection can be reprocessed: wood-plastic board is ecological wood, environmental protection wood, renewable, also does not contain toxic substances, can be processed, cocoa saws, planing, bonding, fixed with nails or screws, etc., easy to install.

F. Appearance: with the natural texture of wood, but also to achieve personalized modeling, product color variety, use will not crack, warping, deformation, and no wood knot scar.